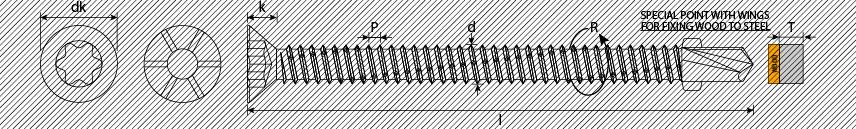

Self-drilling screws tx flat head w/ribs under head cutting thread and special wings

80196

TSP TX W

certifications

regulations

DIN 7504-P (o) T

The recommended screwdriver speed R is purely indicative. The value proposed is based on tests carried out in our laboratories in conformity with regulatory norms. The use of different materials on site may therefore determine values other than those recommended. T value is the drilling capacity.

| Diameters | Limits | dk | k | d | P | TX | R (g/min) | T |

|---|---|---|---|---|---|---|---|---|

| 5,5 | Min. | 10,37 | ~ 3,40 | 5,31 | ~1,81 | T30 | 2.500 | 4,00 |

| Max | 10,80 | 5,46 |

- Carbon steel: C1022

- Case hardness: HV 560 min.

- Core hardness: HV 330-420

- Threaded section: as per listing (Ex 5,5x100/80 = thread 80)

finishing

TG 41

ENDURO

1,000 HR SALT SPRAY TEST

1,000 HR SALT SPRAY TEST

- 10 µm thick fired ceramic coating

- High corrosion resistant chemical conversion film of an approximate thickness of 2 µm

- Metal zinc layer of a thickness ranging between 3 and 5 µm

- Steel substrate

The European Community Directive RoHS (Restriction of Hazardous Substances) which lays down rules on the restriction of use of hazardous substances in electrical and electronic equipment, in order to contribute to the protection of human and the environmental health.

The European Community Directive RoHS (Restriction of Hazardous Substances) which lays down rules on the restriction of use of hazardous substances in electrical and electronic equipment, in order to contribute to the protection of human and the environmental health.packaging

| Sizes | Pieces per Carton | Minimum Consignment | Box |

|---|---|---|---|

| 5,5 x 50 | 1.000 (5) | 400 (2) | 200 |

| 60 | 1.000 (10) | 400 (4) | 100 |

| 65 | 1.000 (10) | 400 (4) | 100 |

| 70 | 1.000 (10) | 400 (4) | 100 |

| 80 | 1.000 (10) | 400 (4) | 100 |

| 90 | 400 (4) | 200 (2) | 100 |

| 100/80 | 400 (4) | 200 (2) | 100 |